COMPAS

Ensuring competitiveness on ammonia production through flexible ammonia plants and low-cost electrolysis

Background

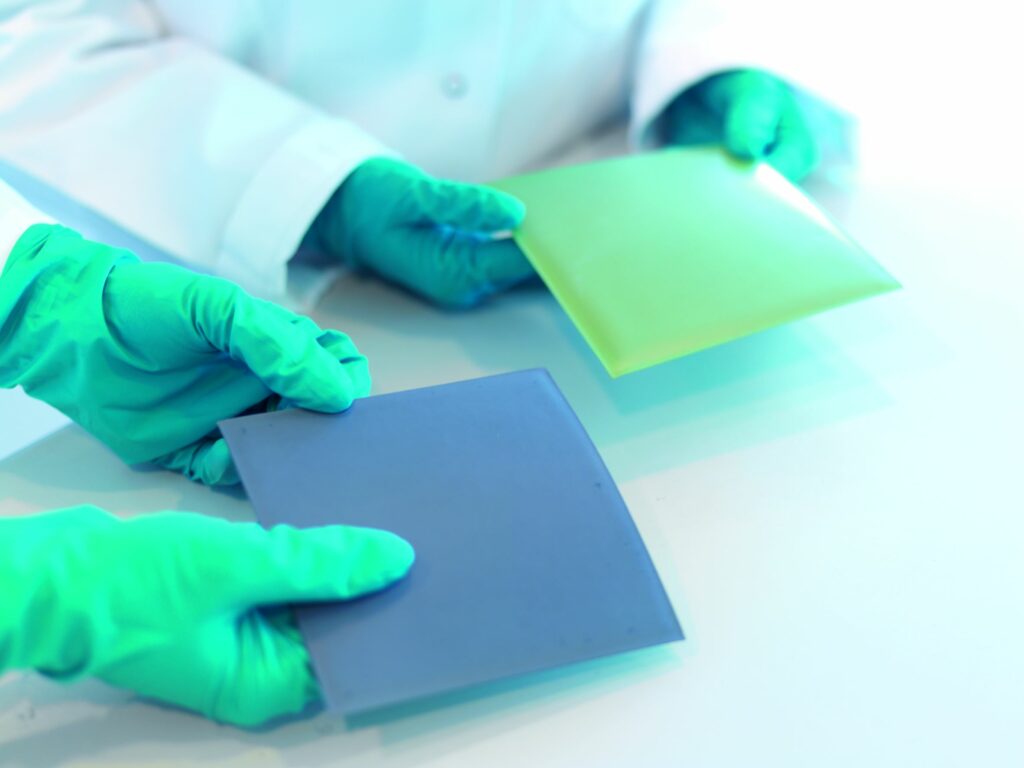

Green ammonia can be produced from renewable electricity such as solar and wind power and will be used for fertilizers world wide. It may also become an attractive fuel for e.g. oceangoing ships. In this green Power to X project, ammonia is derived from hydrogen through electrolysis.

COMPAS is addressing the green ammonia production by investigating the technical and economical requirements for revamping the electrolysis plant of a future green ammonia plant, as technology is likely to improve. This is done to minimize technical risks for first movers.

One key to this is to ensure that the plants are flexible towards technology advancements with respect to the electrolysis technology, as the main operating expense is associated with the electricity consumption of the electrolysis in the green ammonia plant.

The highly energy efficient solid oxide electrolysis (SOEC) technology, may save more than 25 % electricity for ammonia production, with a corresponding impact on renewable electricity and infrastructure installations.

Short video (in Danish) about the COMPAS project. The video has been created by Dansk Center for Enery Storage (link) for their annual meeting in 2023.

Objectives

Besides de-risking on the plant level, the current project targets various improvements over the entire value chain concerning lower cost and competitiveness.

1) Focuses on technological improvements on the cell and stack level of the solid oxide electrolyzer technology – increasing efficiency and durability.

2) Focuses on integration – Optimizing the plant units for the lowest cost of ammonia and

estimating the cost of designing a flexible ammonia plant that allows for change of electrolyser technology.

3) Focuses on the techno-economic assessments of technology upgrades on the flexible ammonia plants – proving and improving the robustness of the SOEC technology towards high current loads and dynamic operation.

Expected results/impact

1) A conceptual design of a flexible ammonia plant allowing for revamp from alkaline to SOEC technology or other electrolysis technology including techno-economic analysis – this will assist early mover investors in making right long-term decisions for their green ammonia plants and will aid in identifying significant potentials for savings throughout the entire value chain.

2) Develop a cell which degrades less than 15 mV/kh at 750ºC and a max of 1.25 A/cm2 over 3000 hours – this will dramatically increase the lifetime of the cells and further increase the competitiveness as well as minimize the resources needed for a green transition.

3) Demonstrate dynamic operation of a SOEC stack-module in lab (TRL 4) – this will greatly impact the view on the technology and aid for future demonstration at system level in a relevant environment (TRL 5).

Budget

34.5 M DKK

Partners

6

Start

October 2022

Duration