PowerLBG

Development of power-to-gas technology for

production of liquefied biogas for the transport sector

Background

Shipping is the backbone of global trade and commerce facilitating 80% of global trade and responsible for 3% of the global greenhouse gas (GHG) emission.

Long-haul shipping is considered to be a hard-to-abate sector, with limited possibilities for electrification opposed to land-based transport. To reduce emissions, parts of the maritime sector has during the last two decades shifted to LNG fuel, to reduce emissions of CO2 and other pollutants associated with heavy fuel oils and marine diesel. However, the LNG is primarily still from fossil origin and will therefore not lead to net decarbonization of the shipping industry.

A CO2 neutral alternative is LBG (Liquefied Biogas), based on liquefied biogas produced by anaerobic digestion of biomasses. These biomasses can originate from wastewater sludge, agricultural waste products, or organic industrial waste streams. In contrast to ammonia, LBG is a ready-to-use renewable drop in fuel, which can be used in existing ship engines. It can therefore be readily implemented. Although the European biogas sector is expanding rapidly, LBG is only estimated to be able to cover a fraction of the total energy demand for shipping fuels. Biomass alone will therefore not be able to cover the use of the shipping sector.

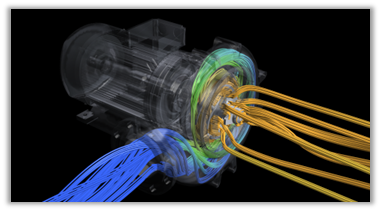

The concept proposed by PowerLBG will use hydrogen produced from local wind turbines and biogas CO2 as feedstock for synthesis of LBG. A mature PowerLBG technology will hence be able to valorize the biogenic CO2 from biogas plants and almost double the LBG output. Several aspects make the PowerLBG technology attractive: (1) It offers a direct utilization of the CO2 in the biogas without prior capture or separation of CO2; (2) it allows on-site methanation omitting the need for CO2 pipelines and transport; (3) it utilizes the microorganisms already present in the existing biogas reactor, reducing the cost for infrastructure and catalysts.

Objectives

- Further development and industrial maturation of the InjectMe methanation technology for methanation of biogas CO2.

- Upscaling of the InjectMe technology, including tests at full-scale

- Development of sensor technology for process control

- Development of a process chain for production of liquefied biomethane/e-methane from biogas methanated with hydrogen produced via electrolysis.

Expected results/impact

The developments of PowerLBG leverage on current infrastructure developments at GrønGas in Hjørring (Figure 2) and will enable the following:

- Production of green drop-in fuel for heavy transport sectors

- Direct production of LBG from biogas without need for prior separation, infrastructure, or transport of CO2.

- Design and evaluation of process chain for localized production of LBG at biogas plants without connection to the natural gas grid.

Budget

11.5 M DKK

Partners

6

Start

January 2024

Duration